AI/ML

AI Agents in Logistics and Supply Chain

Written ByYash Vibhandik

CEO, Bitontree

Published:21 March 2025

15 minutes read

Imagine this scenario: You have an automobile supplier business, and you need to have end-to-end visibility of different types of automobile parts from the stage of manufacturing to delivery. You need to make several emails and phone calls every day to and from the suppliers, distributors, and other points of contact.

When you manage all of these manually, you will have to deal with narrow insights into your supply chain, miscellaneous disruptions in logistics, and insufficient data. That’s a lot of strain, and 60% of businesses suffer substantial losses in revenue due to such inefficiencies.

Now imagine the same scenario with a different context: Your operations are now powered by an intelligent system that can predict demand, automate routine tasks, and reroute shipments instantly, where pallets of goods arrive and depart in perfect synchronization.

This seamless operation isn't just a product of human coordination but also the silent orchestration of AI in Logistics. In fact, companies that are leveraging AI agents in logistics and supply chains are reaping a 35% increase in their operational efficiency and a 50% reduction in human error.

Now the question is - how are these innovation systems redefining the very foundation of our global trade? Read on to explore what AI agents are, their key capabilities, and their applications in transforming the logistics and supply chain industry.

Understanding AI agents and their types

Supply chain management and logistics are changing with the introduction of AI agents in the modern era. You can optimize and increase every feature of your supply chain through the multiple characteristics offered by the sophisticated systems. Now, before we tap into the role of AI agents in supply chain and logistics, let us explore what they are and their functions in brief.

What are AI Agents?

AI agents are software agents developed to be able to realize an environment, perceive its elements, and perform actions to achieve particular goals within it. The system taps into the capabilities of artificial intelligence with human-like decision and interaction capabilities, representing a step up. Moreover, these agents avoid repetitive activities and use data-driven insights that hold immense potential to enhance productivity, improve the experience of your consumers, and fuel your development in the digital age.

Functions of an AI Agent

Did you know that recent research estimates that AI-powered agents can save you 15% on logistics and 20% on inventory? It was made possible with the following defined characteristics of intelligent agents.

-

MCP Servers: AI agents are aware of stock level shifts, transit delays, and demand spikes in diverse geographies.

-

Responsive citations: AI agents can act upon changes in the environment responsively based on observation, such as route optimization for delivery fleets in reaction to traffic updates and dynamically adjusting inventory levels.

-

Reasoning Interpretation: AI agents analyze intricate data and come up with insightful reports to help you in supply chain management. For instance, they will analyze previous sales and market trends to predict the future.

-

Problem-solving: AI bots are also quite smart at solving problems related to logistics. They can deliver services like predictive maintenance on equipment to ensure there is no loss of production, warehouse layouts, and even route optimization models.

Types of AI Agents

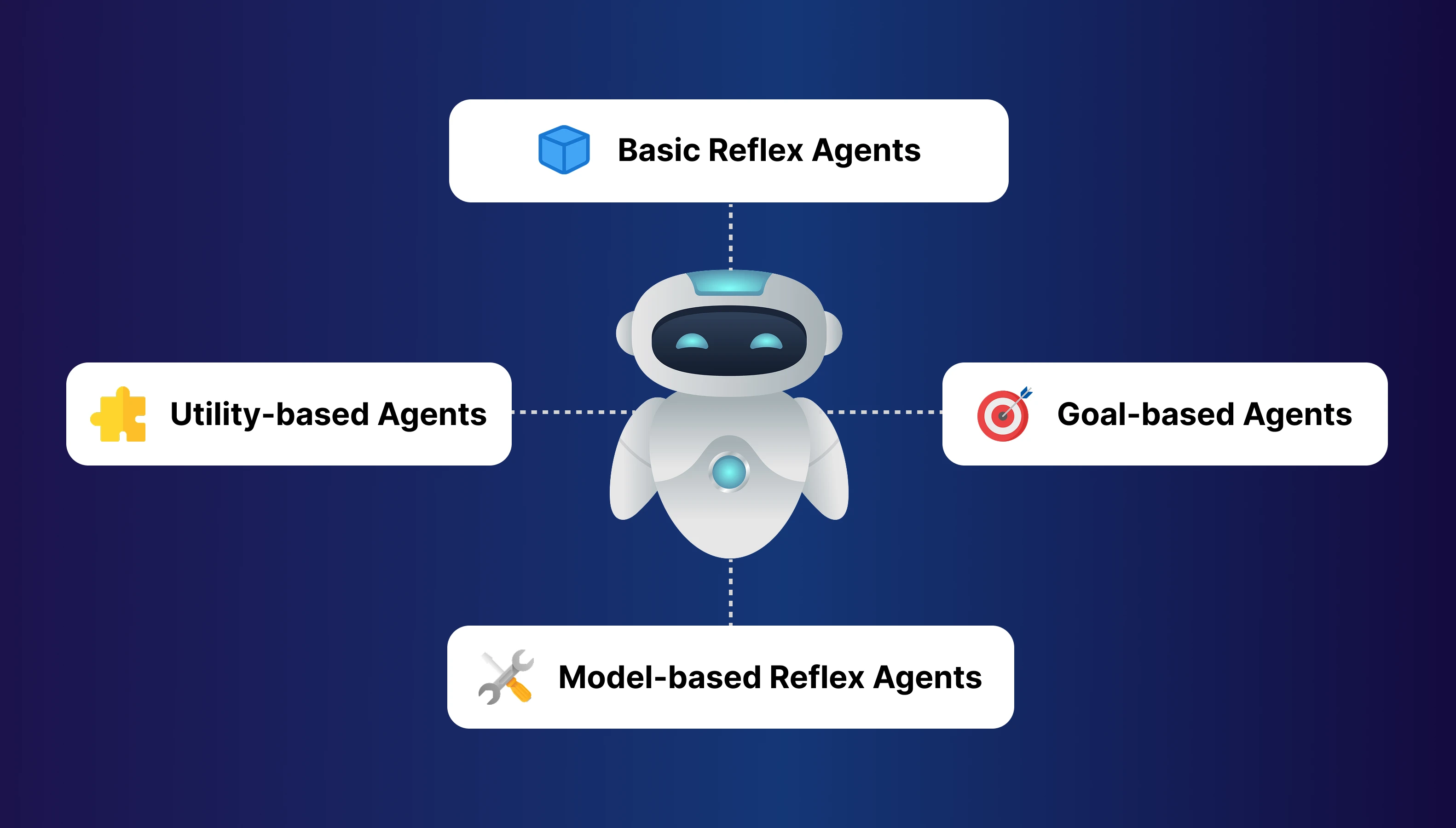

AI agents have been built in a variety of forms, and each one is designed with its unique set of characteristics and applications. Let’s have a breakdown of the common types of AI agents.

-

Basic Reflex Agents: These agents are not capable of creating an internal representation of their environment. Instead, they react instantly to sensory information. They show their best performance when an individual’s present perception is the only factor determining behavior.

-

Model-based Reflex Agents: These agents infer missing information from their experience and present impressions, which helps them deal with partially visible environments. They make sensible judgments, as they will be more equipped to adjust to unforeseen circumstances.

-

Agents with Goal: These agents analyze the possible results of their decisions and make them based on the possibility that their objectives will be achieved. Their ability to plan and choose actions will give desired outcomes, especially in challenging decision-making tasks.

-

Utility-based agents: Utility-based agents are built to assess the relative value by assigning numerical values based on how desirable each potential outcome is to attain the ideal outcome in any given circumstance, where the agent will try to enhance the utility function.

What are AI Agents in Logistics and Supply Chain?

Have you ever wondered how some logistics and supply chain firms maintain optimal inventory levels? Well, this question must have sparked your curiosity, leading you to explore an intriguing question: What are AI agents in logistics and supply chain optimization?

Of course, supply chain inefficiencies cost businesses around $1.3 trillion annually, indicating nearly 10% of global GDP. Similarly, it highlights the complexity of the industry and the need for advanced solutions like Logistics Automation and AI agents to address challenges and optimize processes. Now, this is where AI agents come into the picture - designed to automate, analyze, and optimize supply chain and logistics operations.

AI agents in logistics and supply chains are autonomous robots, software, and programs. They are powered by artificial intelligence technologies like machine learning and data analysis to function as intelligent assistance within the complex world of moving goods.

Key Capabilities of AI Agents in Logistics and Supply Chain

Let’s understand the capabilities of AI agents in logistics and supply chain:

1.) Data Analysis and Prediction

AI agents in logistics and supply chains can collect, process, filter, and analyze huge supply chain data gathered from diverse sources, including historical sales data, market trends, and external factors like weather conditions and economic indicators. They can use this data analysis in supply chain to forecast product demand and find market patterns so that your inventories are fully optimized based on the production schedules.

2.) Route Optimization

AI agents excel in route optimization by integrating real-time data on traffic conditions, road closures, and other variables to choose the most efficient routes for transporting goods. Such seamless optimization helps in reducing transportation costs, improving delivery times, and reducing fuel consumption.

3.) Inventory Management

AI agents in the supply chain are capable of monitoring the stock levels in real-time and tracking their movement throughout the line. For instance, retail businesses can predict the future demand for a specific product. At the same time, manufacturers can use agents in AI to ensure an adequate supply of raw materials to fund the inventory continuously.

Moreover, AI agents can perform ABC inventor segmentation techniques in real-time and allow manufacturers, suppliers, and retail businesses to categorize their products according to the product’s profitability, demand patterns, and shelf life.

4.) Autonomous Decision-Making

Agents in AI can review predefined rules and algorithms while making autonomous decisions, reducing the need for manual intervention and human error. They can efficiently conduct tasks such as choosing the best suppliers, scheduling production runs, and or rerouting shipments.

5.) Customer Service and Communication

AI agents can be integrated into customer service platforms to provide real-time support and assistance to customers. You can make use of them to handle your customer/ supplier inquiries, track shipments, and resolve issues.

Applications of AI agents in Logistics and Supply Chain

Do you remember the oil spill incident when a heavy fog brought China's Qingdao port to a standstill, leaving several container vessels stranded in the Yellow Sea? Events like these highlight the growing need for proactive logistics and supply chain strategies. Let us explore the applications of AI agents in logistics and supply chains.

1.) Data Collection and Integration

If you are in the supply chain domain, you know the biggest challenge is to acquire real-time insights to avoid restricted visibility, faulty decisions and poor collaboration, both within and outside the organisations. AI agents can integrate data from various sources, from supplier databases to IoT devices, to consolidate relevant information for audits and assessments.

When you have data at your hands in a single click, you can make error-free, data-driven decisions. The centralized data repository enables you to make an exhaustive and accurate evaluation of supply chain operations. For instance, Walmart employs AI agents to analyze the history data to predict demand so that they can stock the right products at the right time - neither too much nor too little.

2.) Evaluation of Supplier Performance

Do you want to deliver quality services even when your suppliers are not up to the mark? Feeble and standard suppliers cause disruptions in your quality service, delays, and high lead times. Partnering with such suppliers might cost your business a fortune.

However, embracing AI agents will make it seamless for you to perform unbiased and continual analysis of your supplier’s performance based on various metrics like on-time delivery, quality, and pricing. In this way, you can recognize the steadfast suppliers and negotiate better terms with them.

For instance, SAP’s AI assistant, Joule, provides SAP S/4HANA users with supplier performance insights to managers by analyzing data from SAP systems and third-party sources. It is a chatbot where managers can ask their queries in natural language, and it will provide tailored and context-relevant answers.

3.) Anomaly Detection

The supply chain industry is noisy - erroneous and disintegrated, which might make it challenging for you to distinguish true anomalies from random fluctuations. You need to have accurate detection of product pricing, delivery, and order quality anomalies to streamline the entire supply chain.

AI agents in logistics will help you learn from historical data to identify anomalies that differ from normal patterns, establishing correlations between seemingly unrelated events and automatically generated alerts.

4.) Warehouse Automation

How will you feel when you set up a supply chain where your goods are picked, packed, and delivered automatically? This is now made possible with AI agents, which lead to the highly efficient delivery of products with reduced labor costs. You can embrace AI-powered robots and automated guided vehicles to automate your entire workflow and streamline warehouse-related operations.

Let’s analyze Amazon's warehouse and how they have integrated AI agents to fulfill their operations. AI-driven robots move products efficiently, renting that items are relatives and shipped quickly, thereby improving the delivery process.

5.) Automated Review of Documents

If you are facing inefficient delays, data duplication, and compliance risk, it's because of the poor standard document review process. AI agents, with their ability to leverage NLP (Natural Language Processing) and OCR technologies, will help you by extracting important data from large volumes of documents like contracts, policies, and regulatory requirements.

You can train your AI agents to identify and flag any discrepancies or missing data from the documents. This way, you can be assured of Italy and error-free document handling, leading to the smooth flow of goods in the supply chain.

6.) Risk Assessment and Prioritization

Traditional, human-based risk management approaches only focus on internal risks and side-lying external factors like geopolitical instability. It is subjective and highly biased, which might cause you to underestimate certain risks. In such situations, AI agents will help you build dynamic risk models that cover the interconnectedness of the supply chain and the cascading effects of disruptions. You can use them to simulate risk scenarios and suggest proactive strategies to overcome them.

7.) Shipment Tracking and Monitoring

You have invested your time and effort in producing a good. Now, what would you do if it gets lost or becomes untraceable? Can your business survive with such poorly-tracked supply chain management? In fact, the EMEA region has been reported to have lost 12 million euros due to freight loss and theft.

AI agents are the perfect solution to prevent such hurdles from holding your business back from growing. You can make use of them to track and monitor the shipments effectively. They will send you a prompt alert about any delays or complications - all the while analyzing data about delivery time, traffic patterns, and vehicle mobility.

Key Benefits of AI Agents In Logistics And Supply Chain

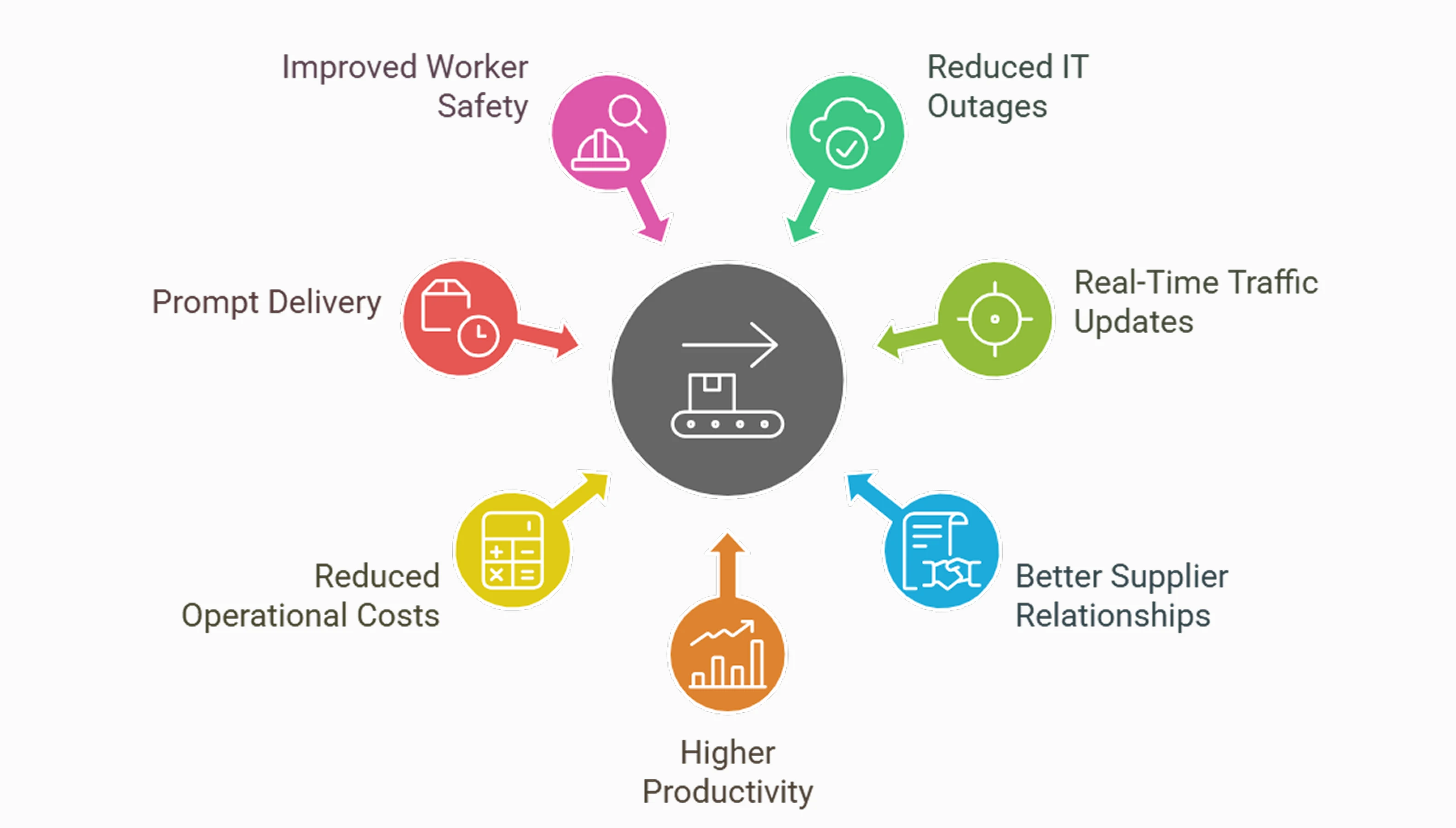

Here are the benefits of integrating AI agents in logistics and supply chain:

1.) Reduced IT Outages

Unplanned IT outages affect the supply chain, causing issues like halted order processing, communication breakdown, and shipment delays. You can use AI agents to learn about the real-time health of your IT domain and set up a fully automated self-healing system, resulting in predictive and timely IT system maintenance.

2.) Real-Time Traffic Updates

Traffic congestion is one of the significant issues for logistics businesses, which might cause several disruptions. You can take advantage of AI agents to monitor the traffic in real-time and find any significant delays. These agents will also help you identify alternative routes, avoid road closures during deliveries, and even predict the surge in the process, thereby optimizing resources accordingly.

3.) Better Supplier-Business Relationship

AI agents in the supply chain will help you share freight data with your supplier without any delays, enable joint demand forecasting, and stay connected around the clock. They will bring your suppliers, vendors, and distributors within a unified platform where they can collaborate in real time and diversify the collected data. It, in turn, fosters a great supplier-business relationship, reducing supplier attrition and promoting loyalty.

4.) Higher Productivity

AI-powered supply chains are proven to be 67% more effective than non-AI supply chains. Wondering why? AI-powered agents are automated, can perform real-time analysis, and have accurate predictive capabilities, mitigating risks and enhancing productivity in your workflow.

5.) Reduced Operational Costs

After deploying AI agents in your supply chain operations, you can save plenty by automating repetitive tasks and reducing rescue wastage. The agents, with their ability to learn from past incidents, will avoid making the same errors in the future, thereby increasing your revenue.

6.) Prompt Delivery

When you take advantage of optimized routes, timely scheduling, and allowing drivers to take the best possible route with AI agents, you can achieve a quick package delivery timeframe. You can even do real-time tracking of trucks and stay updated with the current status of the delivery. If you find any delays, you can devise the best alternatives.

7.) Improved Worker Safety

Thousands of people are facing life-threatening situations in their workplace, which means you can't overlook the safety of your employees. AI agents will help you monitor the safety of your work environment, including storage facilities, warehouses, and assembly lines, allowing you to identify the red flags. Moreover, you can also analyze the vehicle conditions so that they don't have any malfunctions that can lead to major accidents.

Wrapping Up

AI in the logistics and supply chain market is expected to grow at a CAGR of 46.72%, expected to reach USD 40.53 billion by 2030. While the industry is undergoing such a major shift, following the traditional ways just doesn't cut it anymore. With Logistics Automation and AI in Logistics driving smarter decision-making, everything from route options to real monitoring - faster deliveries, better service, and reduced costs is now within reach. But how can you build your AI agent? That’s where Bitontree comes in!

At Bitontree, we are passionate about tapping into the full potential of AI agents for supply chain optimization. We help you leverage the AI agents and continuously refine operations based on live data, learning from every shipment, delay, and challenge. Whether you want to predict disruptions or optimize load planning, we ensure you are always one step ahead.

Partner with us today and provide coverage to create a automated workflow in logistics and supply chain that's ready for the future.

Optimize Deliveries Using AI Agents in Supply Chains!

Frequently Asked Questions

They enhance efficiency by predicting demand, reducing delays, optimizing routes, minimizing costs, and improving decision-making through real-time data analysis.

Yes, AI agents excel at solving complex challenges like demand fluctuations, route disruptions, and inventory imbalances by leveraging predictive analytics and adaptive learning.

Yes, AI agents are scalable and can be tailored to fit the needs of small businesses, helping them compete with larger players by improving efficiency and reducing costs.

They optimize routes to reduce fuel consumption, minimize waste through better inventory management, and support eco-friendly supply chain practices.